РУС ENG |

About the company “Steklomash” / Historical background

G. D. Krasulenkov

“Time has no power” (Russian language)

As far back as 1859, mechanical workshops were established on the territory where current facility is located, at the weaving factories of Savva Morozov, who produced textile equipment and spare parts for it. It was on March 10, 1859, that the date of the formation of the modern enterprise of JSC “Steklomash” was taken into account.

In 1924, the enterprise was given the name of a revolutionary worker-Baryshnikov V. In those years, the production profile of the plant started to change. In addition to the spare parts for the textile industry, the plant began to produce separate units, as well as prototypical mitkel machines. Besides, centrifugal pumps for the chemical industry were built.

In 1966, the plant began to specialize in manufacturing of machines and equipment for the glass-sital industry, and in 1968 the plant was transformed into the “Factory of glass engineering named after Baryshnikov V.”.

The current phase in the company’s development started in 1992, after the transformation of the Steklomash plant named after Baryshnikov V. into the group of companies of JSC “Steklomash”, focusing on glass mechanical engineering.

In 1994, the production diversification begun: the production of insulating glass units of various complexity was mastered.

In 1995 — the production of low-emissivity heat-saving glass started on the technological line of continuous action by magnetron sputtering in a vacuum. The production line was developed and manufactured based on the existing facilities.

In 1996 year — organized the production of new translucent structures from the profile of PVC and aluminum, established production of technological equipment for the glass industry.

2000 year — started to develop a new direction: the production of parts for transport.

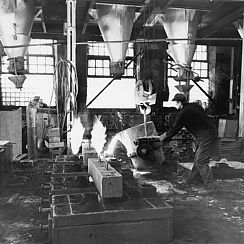

In 2014 , reopened the foundry to produce castings from aluminum and copper alloys by vacuum-film molding.

In 2015, opened a laboratory to conduct research in the field of coating and surface treatment technologies using ion-plasma methods. Organized the manufacture of electronic devices for industrial use with a line of automatic soldering.

In 2016 — began to develop a new direction: the production of wares for transport of composite materials.

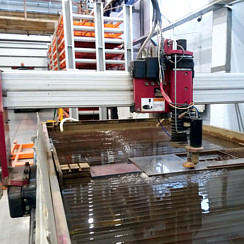

In 2021, a new blanking shop was put into operation, equipped with equipment for laser and waterjet cutting, a stripping machine and a bending complex.

Contact Information